Wastewater treatment is a process used to remove contaminants from wastewater and convert it into an effluent that can be returned to the water cycle. Once returned to the water cycle, the effluent creates an acceptable impact on the environment or is reused for various purposes.

Trade effluent is nothing but the wastewater that is the by-product of any kind of industrial process. The basic process comprises the trade effluent being passed through a screen chamber for removal of floating materials at first and then making it flow to the oil and fat removal tank. From this tank, the effluent is then passed onto the collection and equalization tank, where it gets mixed with air through coarse air diffusers.

From the collection and equalization tank, the effluent is passed through Physicochemical treatment involves a set of processes are coagulation, flocculation and sedimentation.

Next it passes through the FAB Reactor/biological tank, where the bacteria oxidize the organic matter to carbon dioxide and water by the aeration principle.

There are some other tertiary processes for treatment of effluent, which helps in treating waste water and recycling them.

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges. Sewage contains wastewater from households and businesses and possibly pre-treated industrial wastewater. There are a high number of sewage treatment processes to choose from.

Membrane Bioreactor (MBR) process is a combination of biological wastewater treatment solutions and membrane filtration. Biodegradable pollution is reduced using bacteria and microorganisms. After biological treatment, the activated-sludge is separated from the treated water by a submerged ultra-filtration membrane.

MBR facility consists of aerobic tank and anoxic tank. Membrane modules are immersed inside the aerobic tank where organic contents (BOD) in the sewage/effluent will be biologically degraded by activated sludge. The membranes separate suspended solids from liquid through the filtration process. As the pore size of the membrane is 0.1 micron, along with suspended solids bacteria are also removed. There is no need for gravity sedimentation tank or clarifier required by conventional activated sludge systems. Recirculation of MLSS from aerobic tank to anoxic tank reduces nitrate content.

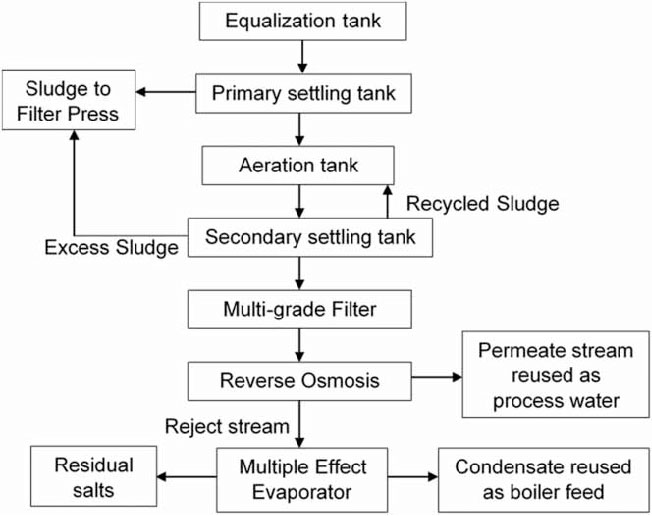

Zero Liquid Discharge (ZLD) is an advanced water treatment technology that recovers nearly all the water and other liquids from industrial waste streams. The resulting concentration of solid matter, which must be disposed of in a landfill, can be as much as 100 times less than would ordinarily be concentrated by conventional wastewater treatment processes. The ZLD System removes dissolved solids from the wastewater and returns distilled water to the process.